Multiphase Flow (Condensation and Evaporation)

Phase transitions are of great importance, especially in the field of hydrogen engines, which can be modeled using suitable condensation and/or boiling models. In combination with fluid-film modeling, a complex multiphase problem can also be evaluated in a single-phase and thus comparatively quickly and cost-effectively. In addition, the determination of critical temperature ranges enables predictions with regard to possible icing.

Multiphase Flow (Immersion Processes and Tank Flow)

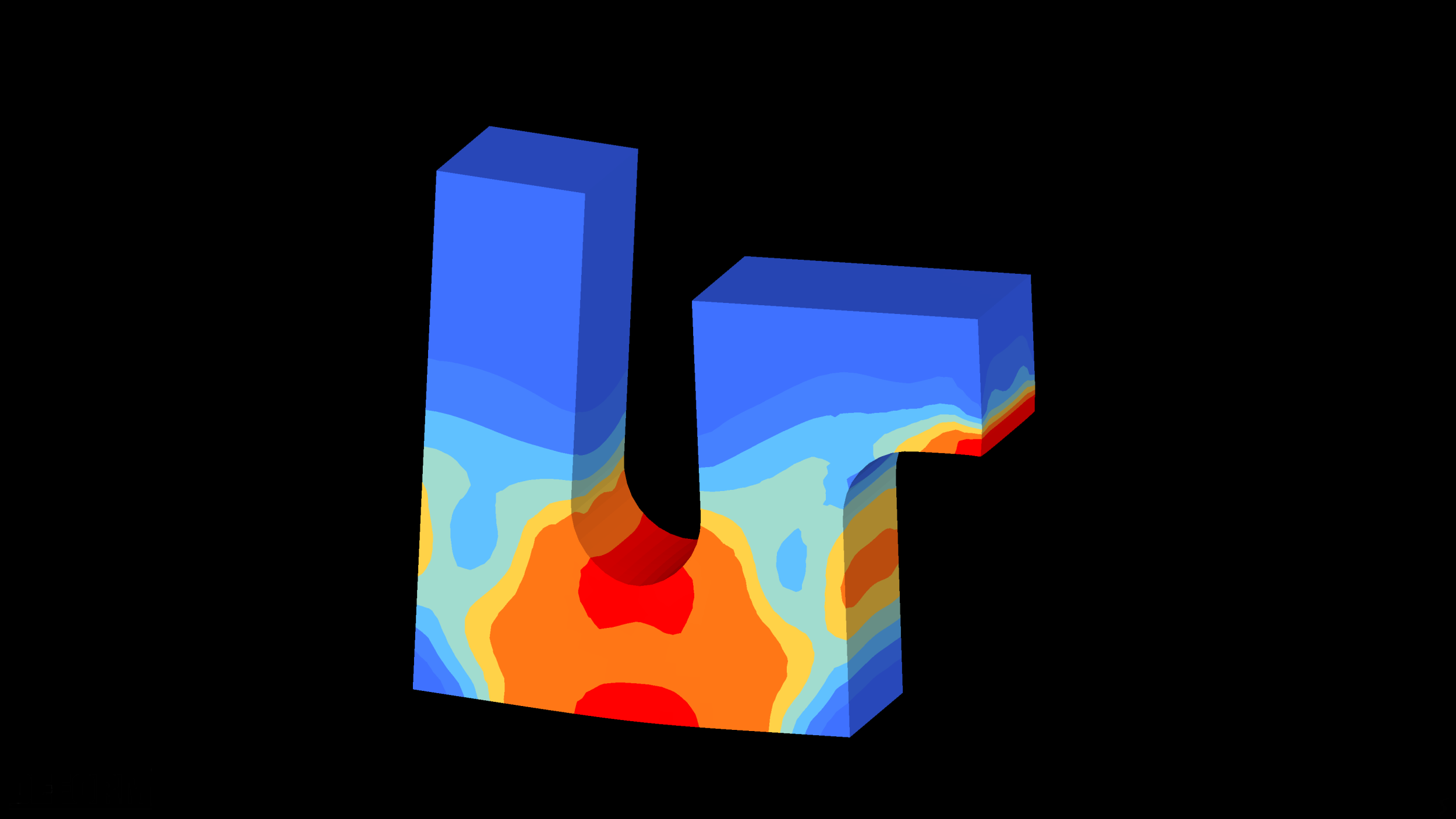

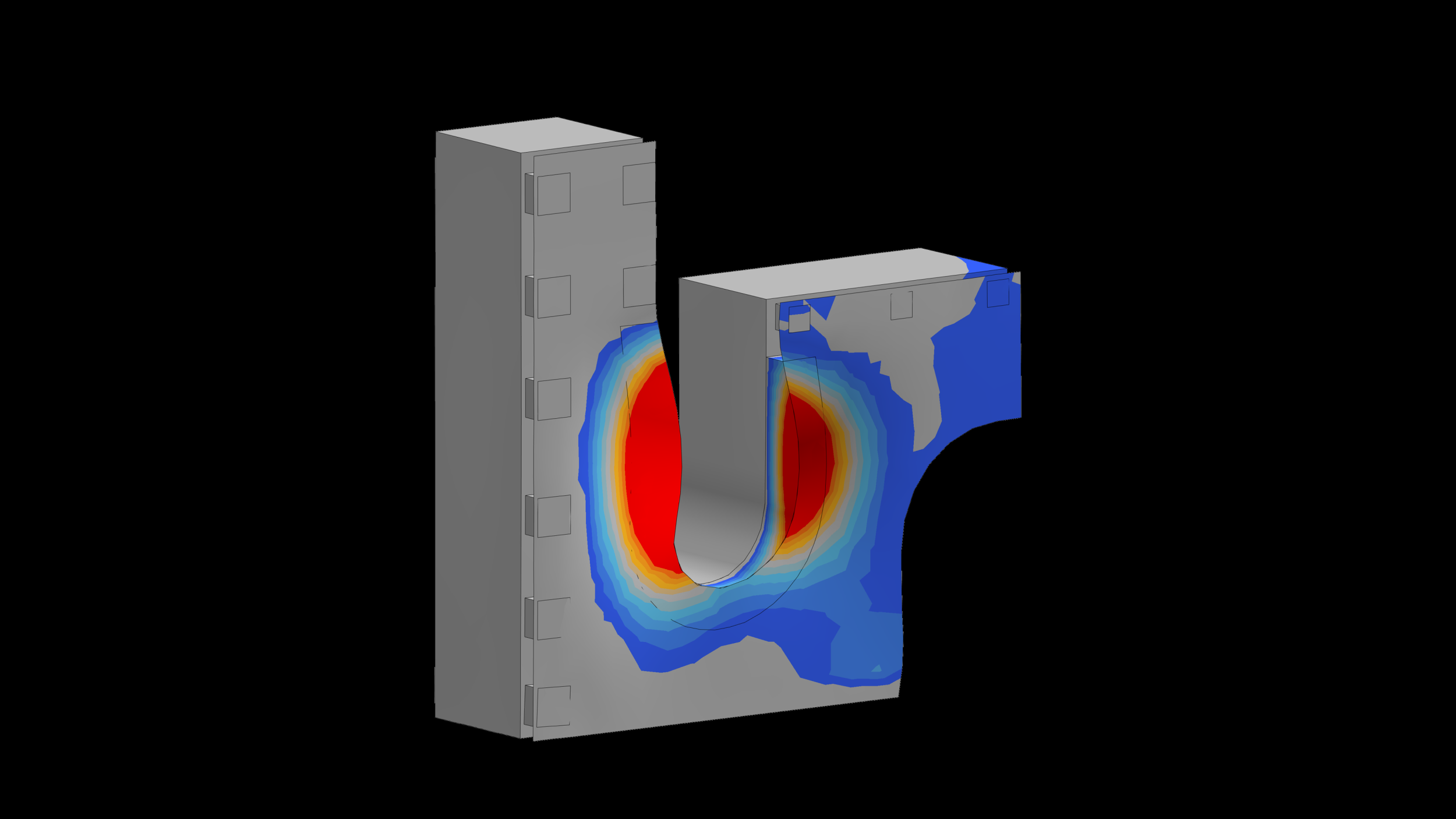

When carrying out immersion processes, various issues are evaluated using CFD and FE calculations. For example, when components are immersed and removed, the resulting pressure differences are investigated, which cause external and internal parts to be pressed together or apart. This entails the risk of plastic deformation and adhesive failure. Pressures, forces, component movements and deformations can be analysed and optimized in order to minimize potential risks.

After the dipping process, residual liquids often remain in the dipped components. A VOF simulation is used to prevent these residual liquids from being carried over into subsequent tanks or burning in the dryer. This determines the remaining liquids, which can then be removed through suitable openings or movements of the conveyor system.

The simulation also provides valuable insights into the flow situation in the tank. Based on the prevailing process conditions, targeted measures can be taken to optimize the flow around the components in order to make the entire process more efficient and reliable.